About Us

AI Power

AI Power was established on January 13, 2020, with a registered capital of 66 million yuan. The factory is located in the Economic Development Zone of Yancheng City, Jiangsu Province, and the factory area has a beautiful and tidy environment. The company has rich experience in product design, manufacturing, factory inspection, commissioning and other aspects.

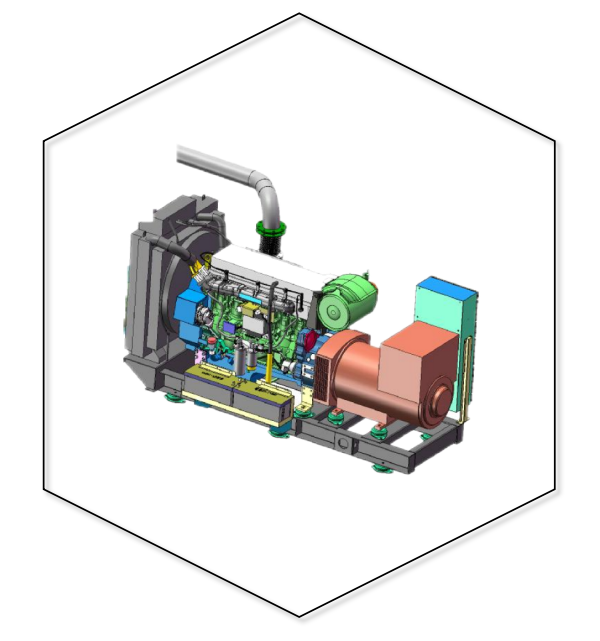

The company mainly deals in engines and generators of brands such as Cummins, Volvo, MTU, Weichai, Yuchai, Stamford, Marathon, and Meiaodi. The power of the generating sets ranges from 10KW to 3000KW, with voltage levels of 400V/11KV, covering a complete range of medium and low voltages. The annual production capacity is 1000 sets. It is expected that the sales revenue will reach nearly 40 million yuan in 2020.

Through production practice and continuous absorption of advanced domestic and foreign technologies, the company's personnel have enabled the production capacity and process manufacturing level of the company's generating sets to reach a very high level in the industry. The generating sets produced by the company are mainly divided into four types according to their uses: land-based, marine, military, and communication. The single-unit power range is from 10KW to 3000KW, with more than 400 specifications. It can provide two or more units for fully automatic paralleling. According to the functions of the generating sets, they can be divided into six series: ordinary type (standard type), automatic type, unattended type, three-remote control type, trailer and van type, and low-noise type. And special specifications can be designed and manufactured according to the requirements of users. According to the requirements of users, diversified production of generating sets such as standard type, trailer and van type, and low-noise type can be realized.

The company's after-sales service always adheres to the tenet of quality first and customer first, takes customer satisfaction as the service standard, and uses superb technology to solve problems for customers, which has been widely praised by customers. In order for users to use the products of our factory normally to complete various tasks and for the products of the factory to give full play to their due effectiveness, the factory conducts professional training for service personnel every year to improve the comprehensive quality of service personnel. At the same time, by taking the opportunity of commissioning and troubleshooting for users, the factory explains the product performance, maintenance, and operation common sense to users, and holds training classes for users, conducts centralized training for users or invites users to the factory for theoretical and practical training to ensure that users master the skills of product use, maintenance, and repair.

Since users of various products are scattered all over the country, in order to provide users with prompt and thoughtful after-sales service, the company has established after-sales supporting service outlets in major regions such as Shanghai, Beijing, Nanjing, Tianjin, Harbin, Guangzhou, Wuhan, Changsha, Xi'an, Chongqing, Lanzhou, and Kunming.

The company's current production equipment mainly includes: processing platform, overhead traveling crane, forklift, air compressor, bending machine, welding machine, 2000KW testing center, with an equipment investment of more than 10 million yuan. The company has obtained OEM authorizations from well-known brands such as Cummins, Volvo, Weichai, Stamford, and Meiaodi. At the same time, it has obtained the third-level qualification certificate for professional contracting of building electromechanical installation engineering, and plans to obtain more than two patent certificates in 2021.

The diesel generating sets produced by the company are widely used in industries such as highways, railways, communications, water conservancy, airports, the military, factories and mines, high-rise buildings,

WeChat

WeChat